1. YAW-J10000 computer-controlled electro-hydraulic servo compression shear test machine manufacturing and test standards :

1. Manufacturing standards

1) GB/T16826-2008 "Electro-hydraulic Servo Universal Testing Machine "

2) GB/T2611—2007 "General Technical Requirements for Testing Machines"

3) JJG139—1999 "Tensile force, pressure and universal testing machine"

4) GB/T3722-92 "Hydraulic Pressure Testing Machine"

5) JJG157-2008 "Verification Requirements for Tension, Compression and Universal Material Testing Machines"

2. Test standard

1) JT/T4—2004 "Highway Bridge Plate Rubber Bearing"

2) JT391-2009 "Highway Bridge Basin Bearing"

3) GB/T17955-2009 "Bridge Ball Bearing"

4) TB/T1893-2006 "Railway Bridge Plate Rubber Bearing"

5) TB/T2331-2013 "Railway Bridge Basin Bearing"

6) TB/T3320-2013 "Railway Bridge Ball Bearing"

7) GB20688.1-2007 "Rubber bearings Part 1: Test methods for seismic isolation bearings"

8) GB20688.4-2007 "Rubber Bearing Part 4: Ordinary Rubber Bearing"

9 ) JT/T822-2011 "Lead core vibration isolation rubber bearings for highway bridges"

10 ) JT/T842-2012 "High-damping vibration isolation rubber bearings for highway bridges"

Two , YAW-J10000 computer controlled servo pressure shear testing machine range

1. This machine is used to test the mechanical properties of the finished product of highway bridge rubber bearings. Can be done separately:

Plate bearing

1) Compressive elastic modulus test

2) Ultimate compressive strength test

3) Shear modulus test

4) Shear bonding performance test

5) Shear aging test

6) Friction coefficient test

7) Allowable rotation angle test

Basin support

1) Vertical bearing capacity test of finished support

2) Test of friction coefficient of finished bearing

3) Rotation test of finished product support

Spherical steel bearing

1) Vertical bearing capacity test

2) Bearing friction factor test

3) Measurement of the rotational torque of the support

4) Horizontal bearing capacity test

2. This product can also carry out all the tests specified in the national standards for railway bridge slab, basin and spherical bearings;

3 . This product can be lead, high damping, isolation vertical stiffness test building support.

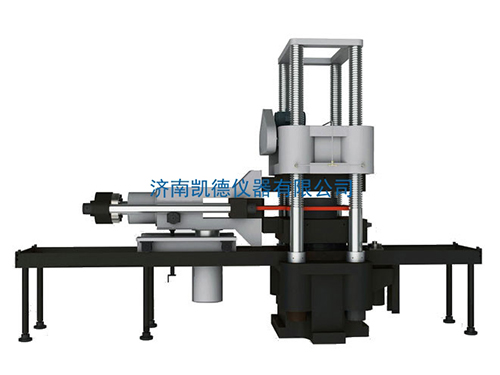

Three , YAW J10000 computer controlled servo-pressure shear testing machine main technical parameters

(1) Vertical loading part

1. Maximum space of testing machine: 1500mm

2. Main actuator: Maximum load: 10000kN

3. Load accuracy: better than ±1% (1%-100%FS)

4. Working piston rising speed: 0~80mm/min (adjustable)

5. Maximum stroke of working piston: 300mm

6. Lower plate: 1050*1050*200mm

7. Test adjustment space: 0-1500mm

8. Lifting speed of beam: 200mm/min

9. Displacement accuracy: better than ±1% FS

10. Advancing and retreating of trolley type lower pressing plate: motor drive

11. Shearing cylinder and reaction frame advance and retreat: motor drive

12.Displacement resolution: 0.01mm

13. External dimensions of the host: 1850x1220x4200mm

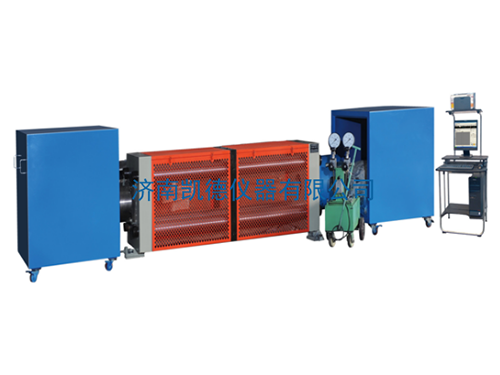

14. Hydraulic source size: 1150x1000x1500mm

15. Control cabinet shape: 1180x840x1380mm

(2) Test mechanism for shear elastic modulus

1. Maximum horizontal shear force of horizontal actuator: 2000kN

2. Display accuracy: better than ±1% (1%-100%FS)

3. Pushing speed of working piston: 0-50 mm/min (adjustable)

4. Maximum stroke of working piston: 150mm

5. Displacement accuracy: better than ±1% FS

6. Displacement resolution: 0.01mm

(3) Part of the corner test mechanism

1. The maximum angle of the angle actuator ejection force: 600kN

2. Display accuracy: better than ±1% ( 1 %-100%FS)

3. Pushing speed of working piston: 0-60 mm/min (adjustable)

4. Maximum stroke of working piston: 100mm

5. Displacement accuracy: better than ±1% FS

6. Displacement resolution: 0.01mm