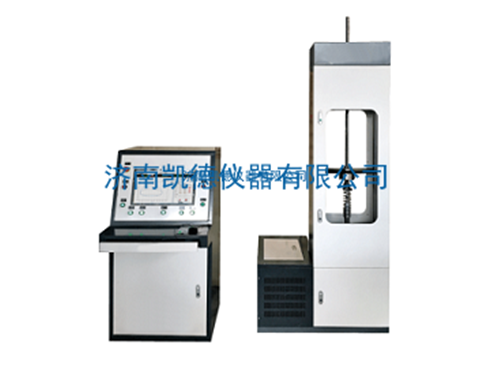

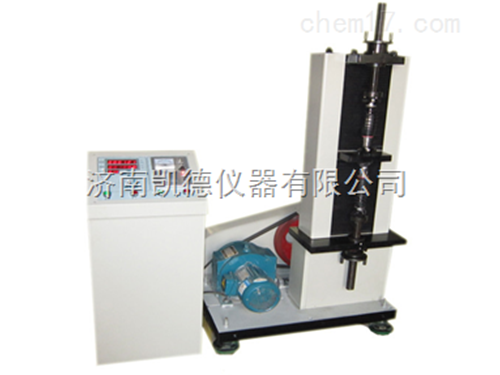

1. Purpose:

The PWS-10 electro-hydraulic servo shock absorber comprehensive performance test bench adopts electro-hydraulic servo control technology, which is suitable for dynamic and static performance tests (indicating power test, speed characteristic test) and fatigue life test of various cylindrical shock absorbers ( Durability test), temperature characteristic test, etc. The test method meets the standards stipulated in "Test Method for Automobile Tube Shock Absorber Bench" (QC/T545-1999), "Technical Conditions and Test Methods of Motorcycle and Moped Shock Absorbers" (QC/T62-2007) related requirements.

2. Main technical indicators:

1) Maximum static test force: ±10KN, indication accuracy ±1%, accuracy range 2%-100%FS.;

2) Maximum dynamic test force: ±10KN, dynamic fluctuation ≤±1%FS.;

3) Frequency range: 0.1-10Hz;

4) Maximum stroke of actuator: ±125mm, indication accuracy ±1FS.;

5) Main Test waveforms: sine, square, triangle, T-wave, ramp and other command waveforms or external input waveforms;

6) Constant pressure servo pump station: pressure 21Mpa, flow 70L/min, power 30KW, filtration accuracy 3µ;

7) Control Controller: KDWinTster all-digital hydraulic servo controller based on PCI bus;

8) Control mode: force and displacement all-digital PID closed-loop control, the control mode can be switched smoothly and without disturbance;

9) Closed-loop control frequency: 1kHz;

10) Test signal measurement resolution Rate: ≥1/200,000, indication accuracy 0.005FS.;

11) Signal generator accuracy: 0.01%;

12) Maximum test speed: 1.2m/s;

13) Maximum test space (the upper end of the actuator to the bottom of the force sensor End surface): ≥1200mm;

14) Test space adjustment method: hydraulic lifting and locking beam;

15) Test station: one characteristic test station, two fatigue test stations;

16) Data processing method: computer screen display test parameters , Automatically draw the test curve.

17) Optional: temperature control range of the environmental chamber: -30°C—120°C;