This system is suitable for the transformation and upgrading of the bottom-mounted 100kN-2000kN hydraulic universal testing machine to WAW microcomputer controlled electro-hydraulic servo automatic control, electronic measurement and acquisition of test data, programmable automatic test, automatic analysis, printing reports and curves. The main engine applicable to this system includes the lower oil cylinders and two-way oil cylinders of Jinan, Changchun, Hongshan and other manufacturers.

Modified standard configuration and use

1. Hardware part

1) HP commercial PC, used for automatic control and data processing;

2) HP laser printer, used to print reports and curves;

3) PCI interface AD700 (C+) universal test card, used for electronic signal amplification and data acquisition;

4) Special UTB-S electric control box for power amplification of electro-hydraulic servo system;

5) Precision pressure sensor for measuring test force;

6) Electronic extensometer, used to measure deformation;

7) Photoelectric encoder for measuring the displacement of the beam;

8) Proportional servo valve group;

9) Servo oil source system, including cooler, oil filter, etc.;

10) Other installation accessories and connectors;

2. Software part

1) UTC for Windows98/2000/XP installation software, AD700 driver provided;

2) VAC universal measurement and control drive for real-time data acquisition and closed-loop control;

3) MaxTest software (WAW standard version), used for dynamic display of test data and curves, ATP automatic test program control, material performance index analysis, report printing and database management;

3. Main functions and technical performance

1) Comply with the relevant regulations of GB228-87 national standard;

2) The AD700 card complies with the PCI bus standard, and the computer automatically recognizes and installs it to achieve "plug and test";

3) MaxTest software runs on Windows98/2000/XP operating system;

4) Select original brand-name integrated devices such as BB, AD, Xilinx, etc., and fully digital design;

5) The electronic measurement system has no manual adjustment components such as potentiometers to ensure interchangeability and facilitate maintenance and replacement;

6) Built-in large-scale CPLD programmable device, with high-speed computing capability, real-time processing of digital signals;

7) Integrated dual-channel precision instrument programmable amplifier, digital zero adjustment, automatic gear shift;

8) Digital display of test force and peak value in 4/5 levels, with an accuracy of ±1% of the starting value at 20% of each range;

9) Test force overload protection, and record the history log for future reference;

10) Digital display deformation in 4 levels, the accuracy is ±0.5%FS starting from 20% of each range;

11) The measurement resolution of beam displacement is 0.01mm;

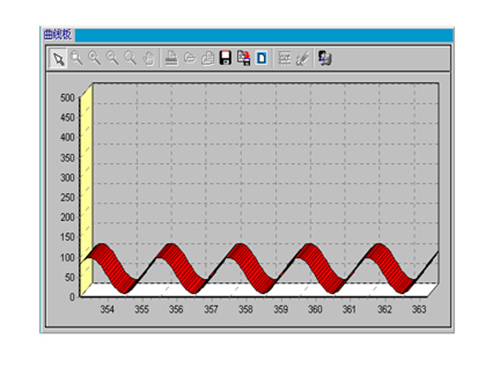

12) Real-time recording and dynamic display of multiple test curves such as test force-deformation and test force-displacement;

13) Adopt SuperSliding closed-loop control strategy, which has the characteristics of small overshoot, fast response and strong robustness, and realizes constant velocity stress, constant velocity strain, constant velocity displacement and other control modes;

14) During the test, the control mode can be dynamically switched, continuously variable, and smooth transition;

15) Provide the original ATP programmable automatic test program, which can create, modify, and save the automatic test program and its parameters, such as different forms of automatic metal tensile test;

16) Optional low-frequency dynamic test control, providing triangle wave, trapezoidal wave, sine wave and any editable waveform;

17) Using human-computer interaction to analyze and calculate the mechanical performance indicators of the tested material, it can automatically calculate the elastic modulus, yield strength, non-proportional elongation stress, etc.;

18) Use standard database to manage test data and support batch test;

19) It can be backed up, read, and summarized through the departmental local area network, and the test report can be printed in the specified format;

20) Optional plotter (purchased separately) to output large format test curves;

21) Optional MaxReport software to customize special test reports;

3. Service content

1) Modification of the main engine hydraulic system;

2) Servo oil source system installation, 72-hour cycle fine filtering and washing oil;

3) Installation, debugging and calibration of measurement and control electrical equipment;

4) Microcomputer software installation and initial setting;

5) Two days of on-site training;

6) Provide one-year free equipment warranty;

7) Provide three-year MaxTest software (WAW standard version) free upgrade;

8) Internet technical support (C-type registered membership);

9) Optional configuration (purchase separately)

Roland plotter output A3 format stretch curve; MaxReport software customized special test report and form;